Technical Information

- Extensive Experience and Expertise in Aircraft Jet Engine Component Manufacturing

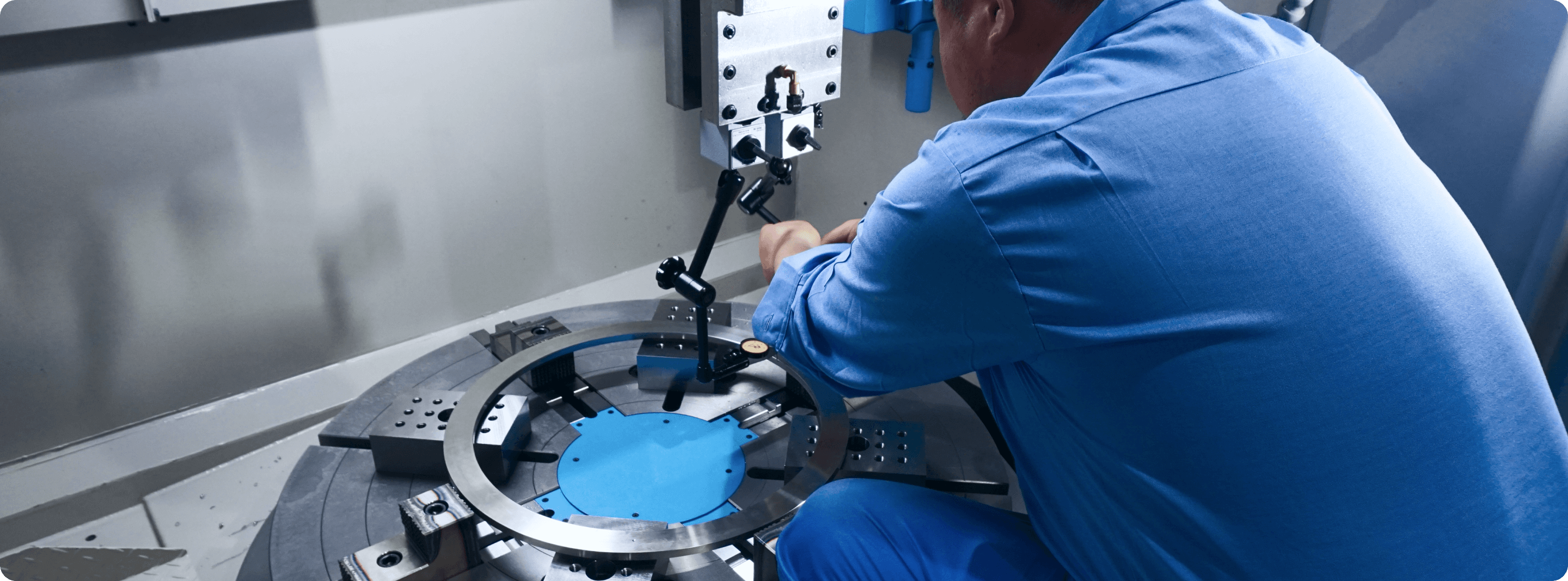

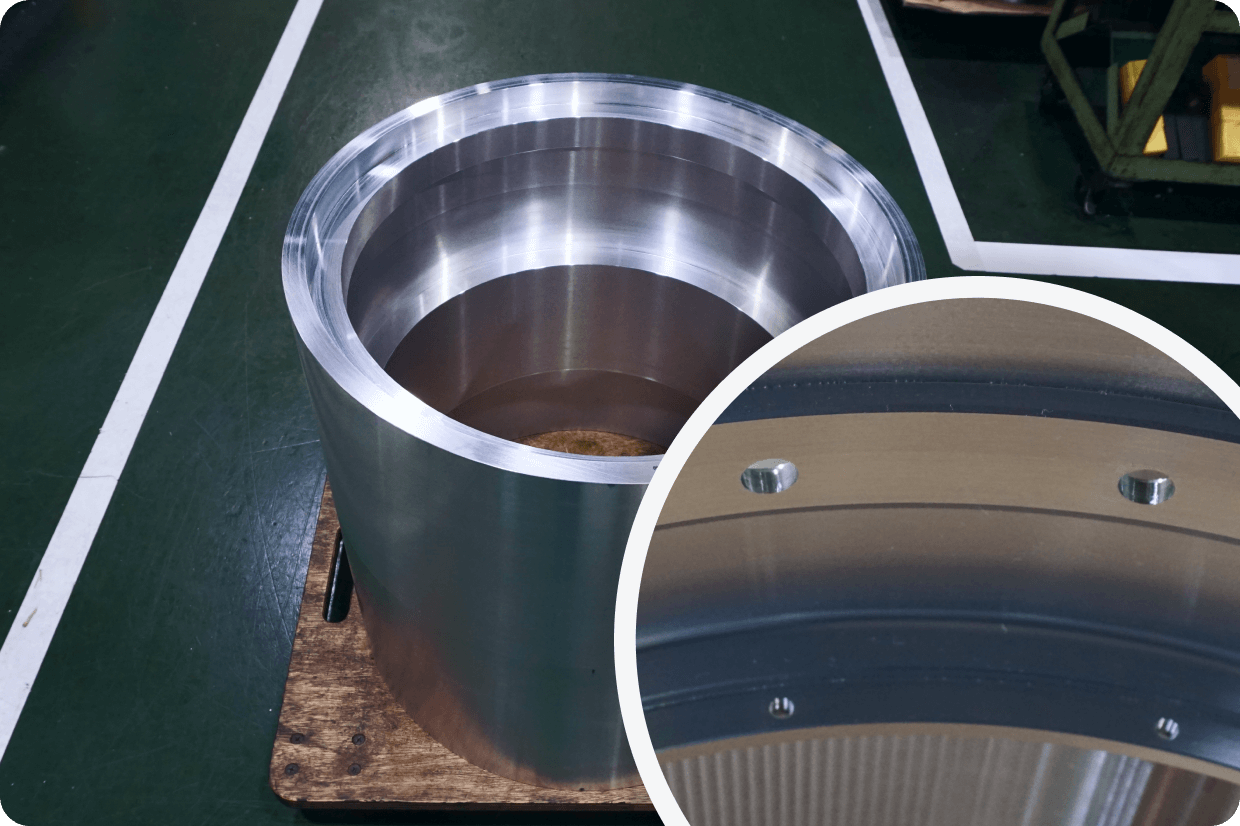

- With nearly 60 years of experience in manufacturing aircraft jet engine components, our company has accumulated advanced technical expertise, extensive experience, and specialized know-how in the machining of easily deformable thin-walled parts.

In addition to a wide range of machining technologies such as turning, milling, grinding, and electrical discharge machining, we are also capable of coordinate measurement machine and non-destructive testing. This allows us to establish an integrated production system that covers everything from process design to inspection.

Our ability to seamlessly integrate multiple processes is a unique strength that sets us apart from competitors, enabling the stable supply of high-precision, highly reliable products.

Capability in High-Precision and Hard to Machine Material Processing

Leveraging state-of-the-art equipment and advanced technical capabilities, we specialize in high-precision machining, complex-shaped components, and processing of difficult-to-machine materials.

We take pride in our ability to deliver high levels of customer satisfaction, especially in the production of parts that must meet the stringent quality standards demanded by the aerospace and semiconductor industries.

Our expertise includes machining of challenging materials such as nickel alloys, titanium alloys, cobalt alloys, stainless steel, and super duralumin.

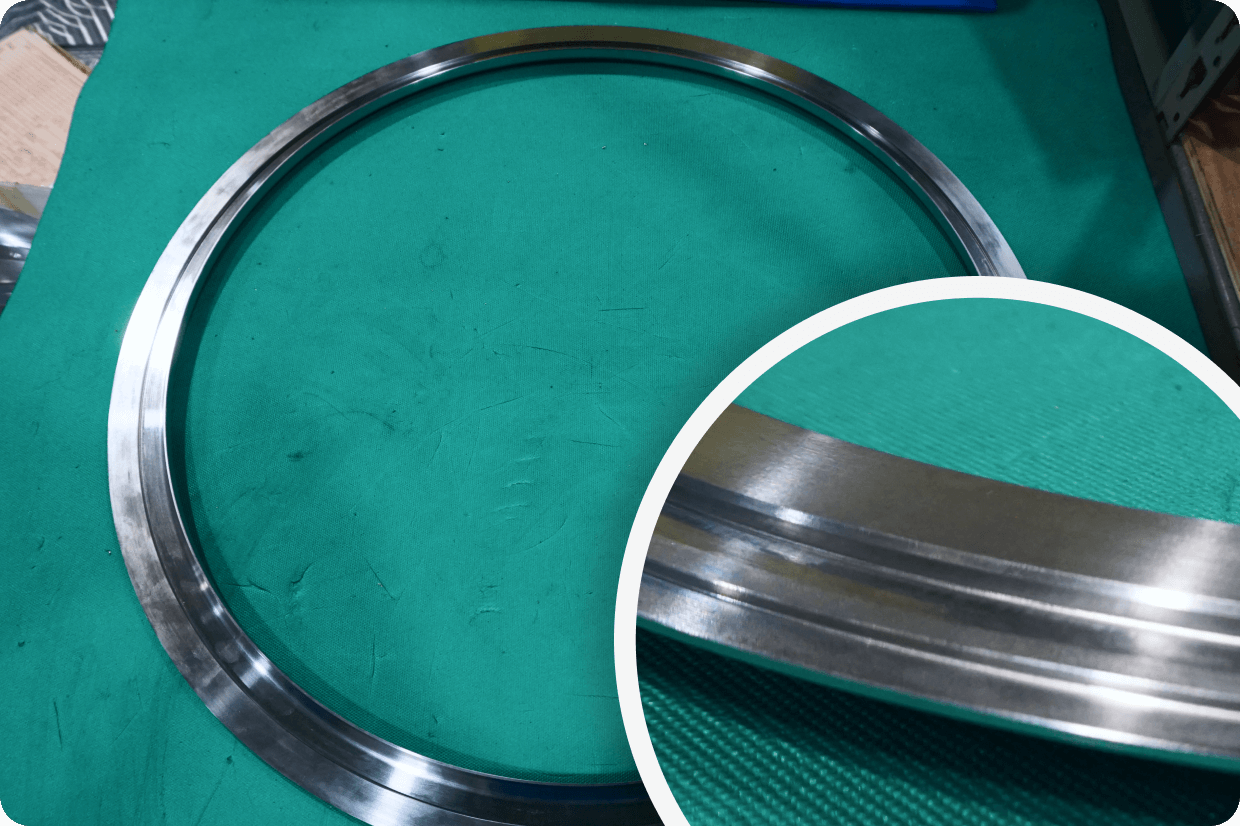

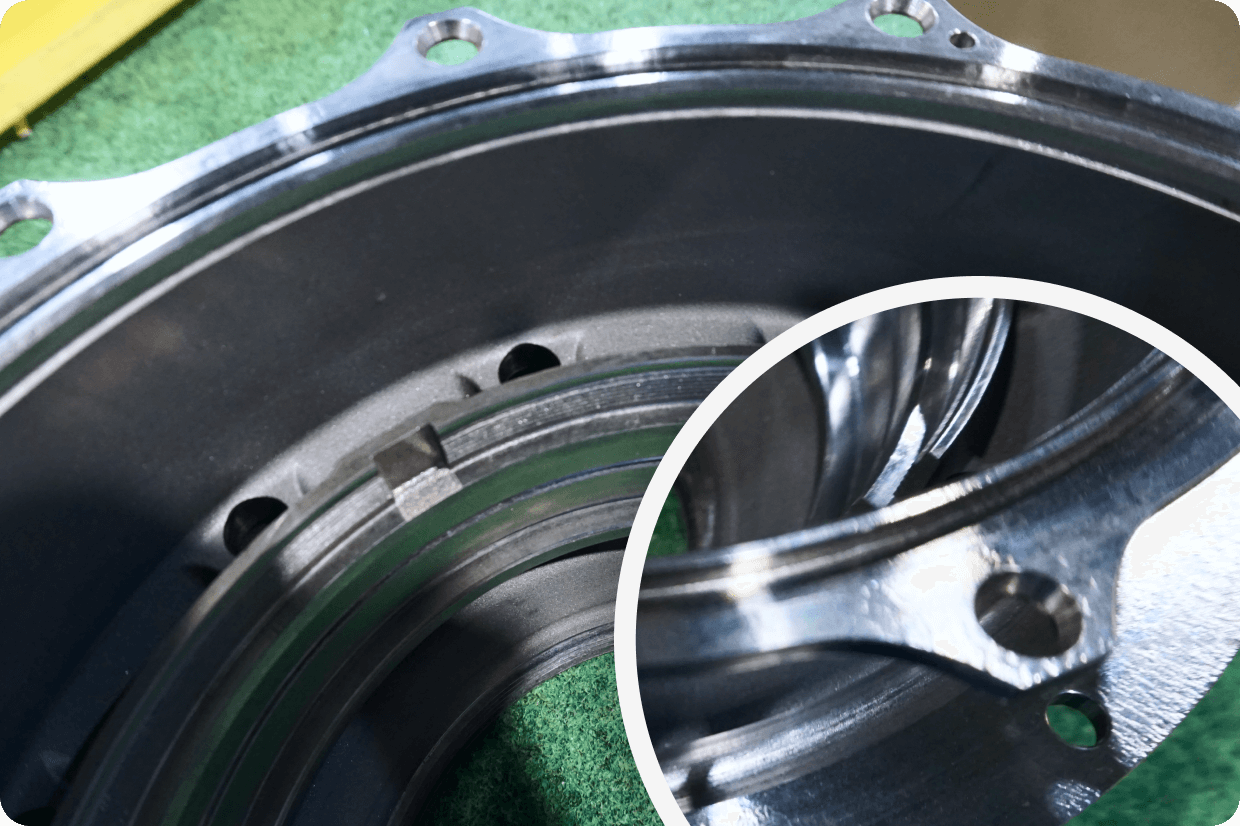

We specialize in machining difficult-to-cut materials such as nickel alloys, titanium alloys, cobalt alloys, stainless steel, and super duralumin. We are also capable of precisely machining complex, thin-walled ring shapes (1mm to 1.5mm thick), including deformation control, to meet dimensional specifications.

Our production capabilities cover a wide range of part sizes and shapes—from small components like 1 mm-diameter pins and 0.5 mm-thick spacers, to large components such as 1,800 mm-diameter ducts, rings, and casings, as well as 1,500 mm-long tubes and shafts.

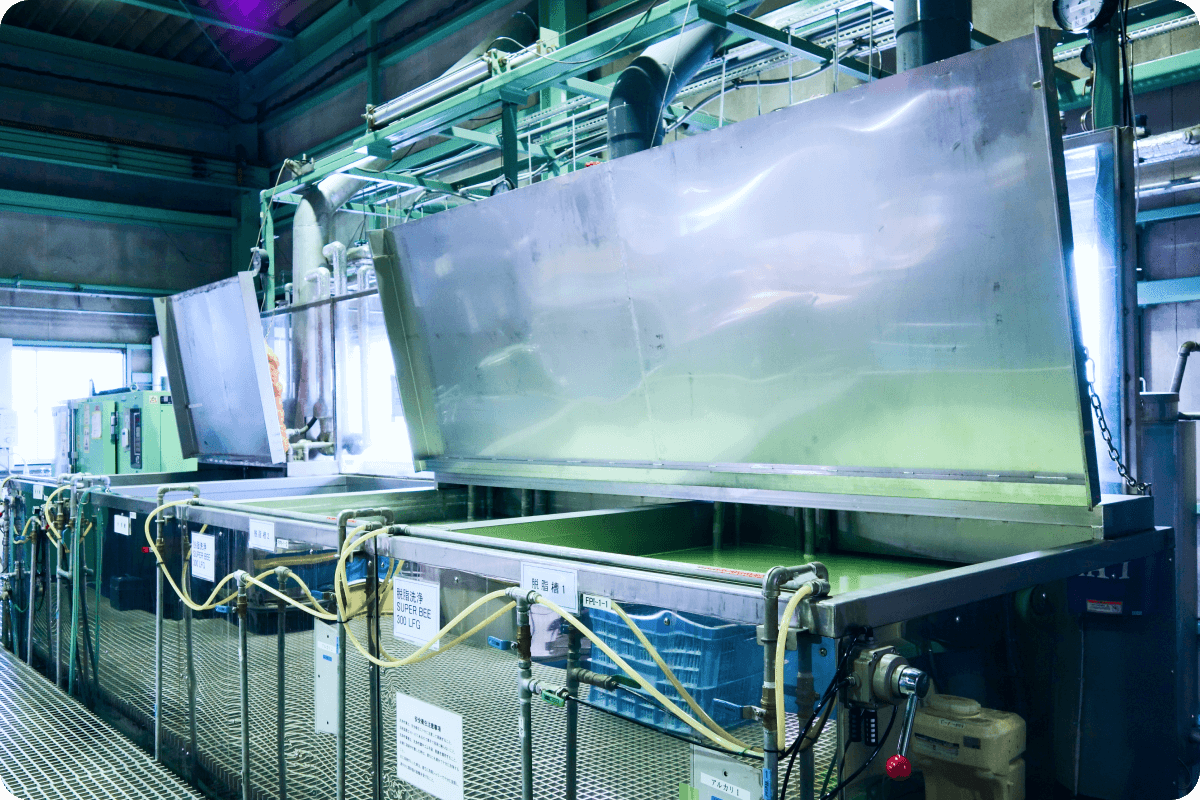

Fluorescent Penetrant Inspection

Fluorescent Penetrant Inspection (FPI) is a type of non-destructive testing used to detect minute cracks and surface defects on metal components. This method plays a vital role in the inspection of aircraft parts, where the highest levels of safety are required, as it enables the precise detection of extremely small surface flaws without damaging the part itself.

FPI must be performed by certified inspectors who have passed written exams, practical tests, and vision tests.

The inspection process involves applying a penetrant liquid containing special fluorescent dye to the surface of the component. This penetrant seeps into any cracks or flaws present. After a designated dwell time, excess penetrant is carefully removed, and ultraviolet (UV) light is then applied. The dye trapped in surface discontinuities fluoresces under the UV light, making even the tiniest defects clearly visible—ones that would be impossible to detect with the naked eye.

Main Products

Aerospace-related components

Titanium alloy components

Nickel alloy components

Aluminum alloy components

Semiconductor manufacturing equipment parts

Source: NHK SPRING Website

Machinery & Equipment

Here is an overview of the machinery and equipment we own.

NC Vertical Lathe(Turning)

- O-M TM2-12N/16

- Qty 3

- YAMAZAKI MAZAK MEGA TURN 600

- Qty 1

- O-M RT-915

- Qty 1

- O-M VL-6N/6NT

- Qty 2

- O-M OMEGA 50

- Qty 5

- O-M VTLex 915

- Qty 5

NC Complex Vertical Lathe

- O-M Neoα-10EXⅡ

- Qty 2

Vertical Lathe

- O-M VTO12(φ1200)

- Qty 2

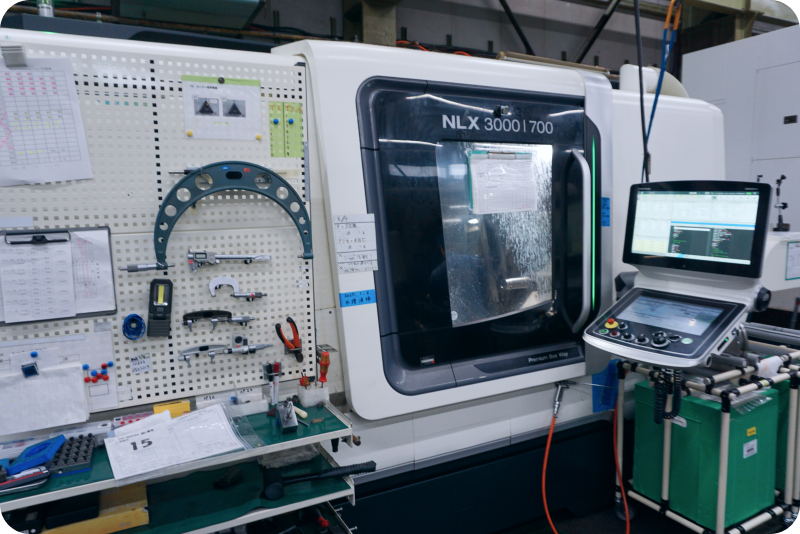

NC Horizontal Lathe

- DMG MORI NLX3000/700

- Qty 2

- DMG MORI NLX4000/750

- Qty 2

- DMG MORI SL403C/800

- Qty 6

- DMG MORI SL603C/1000

- Qty 1

- DMG MORI TL-40(2000)

- Qty 1

- DMG MORI SL-25MC/500,SL-25B5

- Qty 2

- DMG MORI CL-20,SL-303B

- Qty 2

- DMG MORI J-5

- Qty 3

- YAMAZAKI MAZAK QT-250

- Qty 1

- YAMAZAKI MAZAK SQT200,QT-15N

- Qty 2

- DAINICHI KINZOKU KOGYO DL75,DL95

- Qty 2

- Okuma ACT-2SP-2

- Qty 1

NC Complex Horizontal Lathe

- DMG MORI NLX2000,NLX2500Y-700

- Qty 1

Horizontal general-purpose lathe

- DMG MORI HB-725/575,MS-850/650

- Qty 7

5-Axis machining center

- MITSUI SEIKI KOGYO HU63A-5X,HU80A-5X

- Qty 2

- MITSUI SEIKI KOGYO Vertex75xⅡ,Vertex75x3

- Qty 3

- HERMLE C52U

- Qty 2

Horizontal machining (4-Axis)

- MITSUI SEIKI KOGYO HU-50A

- Qty 2

- YAMAZAKI MAZAK FH-6000

- Qty 1

- YAMAZAKI MAZAK H-500/50N

- Qty 3

Vertical machining (3-Axis)

- MITSUI SEIKI KOGYO VU50A,VU65A

- Qty 6

- MITSUI SEIKI KOGYO VJ4A

- Qty 1

- YASDA PRECISION TOOLS YBM-950V

- Qty 1

- DMG MORI NVX5060/40,SV-500B/40

- Qty 2

- YAMAZAKI MAZAK VTC-41

- Qty 2

- YAMAZAKI MAZAK FJV-250,MTV-655

- Qty 2

NC Horizontal boring machine

- TOSHIBA MACHINE BTD-200QE

- Qty 1

Horizontal boring machine

- KURAKI BM-10

- Qty 1

- KURAKI BZ-8

- Qty 1

- Shinada SB80

- Qty 1

NC fraise

- SHIZUOKA MACHINE TOOL / Okuma VHR-AP,ST-NR

- Qty 2

High speed NC fraise

- TOSHIBA MACHINE SCP-A3

- Qty 1

Vertical fraise

- SHIZUOKA MACHINE TOOL / Makino VHR-A,SV-CH,KVJP-55

- Qty 3

Horizontal fraise

- Hitachi Seiko MS-P

- Qty 1

Electrical Discharge Machining

- Kuroda Precision Industries SD-70

- Qty 1

NC Electrical Discharge Machining

- Sodick EPOC-4

- Qty 1

- Mitsubishi Electric EX-30,M35J

- Qty 2

- Hitachi Seiko HDS-10

- Qty 2

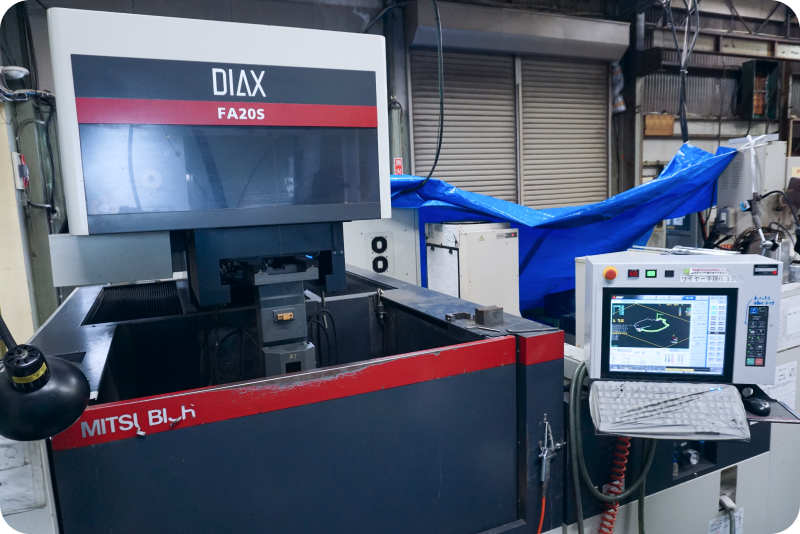

NC Wire-cut

- Mitsubishi Electric FA20S

- Qty 1

- FANUC tape cut L,FTC-W1

- Qty 2

Surface grinding machine

- Okamoto machine Tool Works PSG-63DX

- Qty 2

- Okamoto machine Tool Works PRG6DXNC

- Qty 1

- SANSEI GK-8

- Qty 2

Roraty Surface grinding machine

- SANSEI SS-5F

- Qty 1

NC Roraty Surface grinding machine

- Okamoto machine Tool Works PRG-6DXNC

- Qty 1

NC External cylindrical grinding machine

- TSUGAMI G18AB,G18-Ⅱ

- Qty 2

External cylindrical grinding machine

- TSUGAMI GU25

- Qty 1

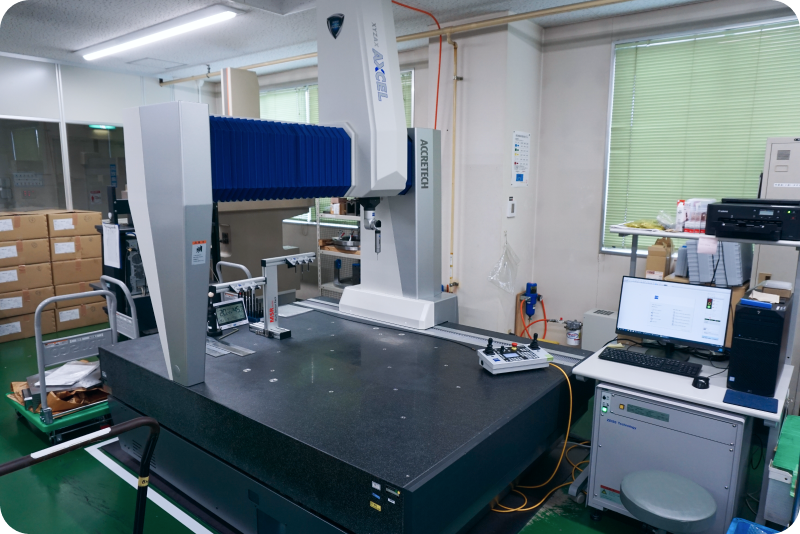

Three-dimensional measuring instrument

- TOKYO SEIMITSU XYZAK AXCEL RDS 10/12/6

- Qty 1

- TOKYO SEIMITSU XYZAK AXCEL RDS 12/15/10

- Qty 1

- Mitutoyo A121

- Qty 1

- Mitutoyo F905

- Qty 1

- Mitutoyo BRIGHT

- Qty 1

- Mitutoyo CRYSTA-Apex S544

- Qty 1

- Mitutoyo CRYSTA-Apex V9166

- Qty 1

- TOKYO SEIMITSU Fusion-NEX 10/15/6

- Qty 1

- TOKYO SEIMITSU SVA fusion 9/10/6

- Qty 1

- Nikon Metrology ALTERA Plus 10.10.8

- Qty 1