About Us

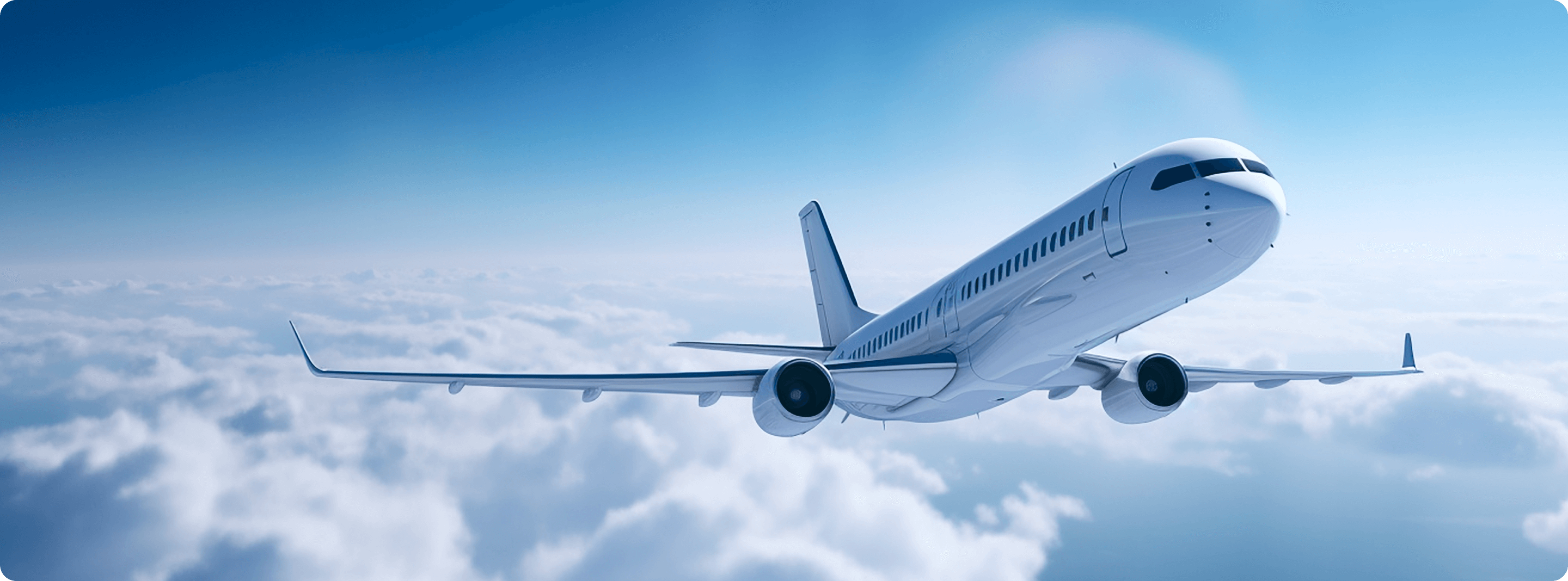

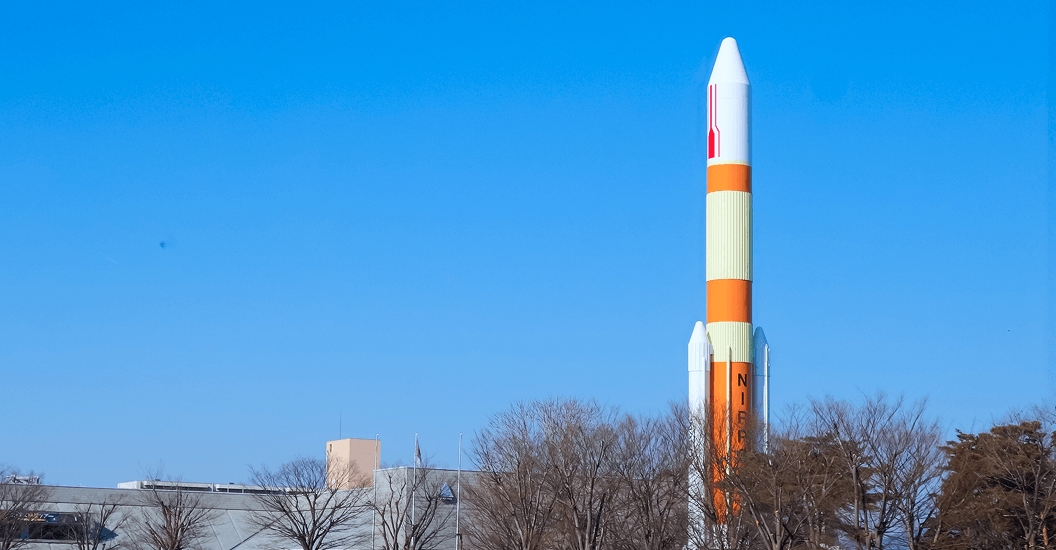

- Reliable Technology Supporting Japan’s Skies

- A rocket kicks off the ground and pierces straight through the clouds.

Behind that moment are people who dedicate countless hours and advanced technologies.

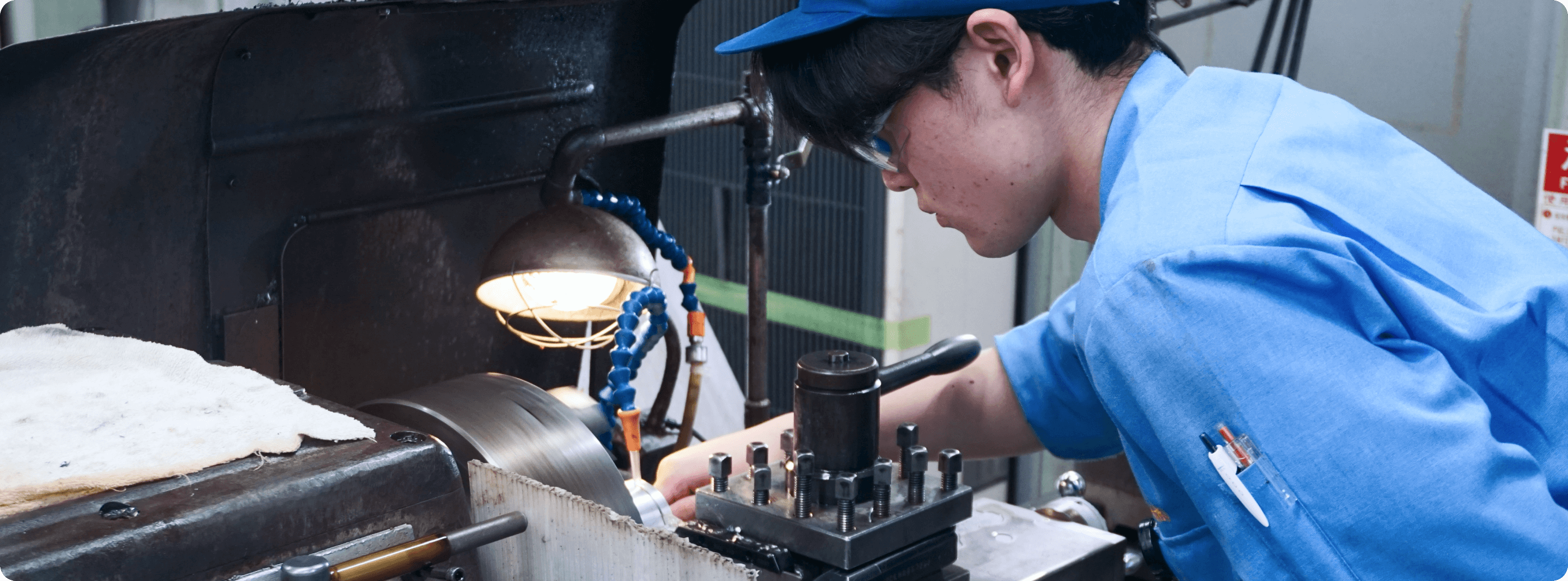

Rocket components and aircraft jet engine parts often take months to produce and are so delicate that even a 0.001 mm deviation can lead to rejection.

We are a manufacturer that takes pride in craftsmanship, meticulously and precisely finishing each part.

Main Products of CosmoSeiki

CONDUCTOR

Commitment to Quality

Components for aerospace applications and semiconductor manufacturing equipment demand exceptionally high levels of precision and quality due to the nature of their use.

Even the slightest error or defect can significantly affect the overall performance and safety of the product, which is why a strict and meticulous finish is always required.

These products are often used in extremely harsh environments, where durability, reliability, and reproducibility must meet the highest standards—far beyond those of many other industries.

To meet such demanding requirements, we have continuously refined our technical capabilities.

We go beyond simply adhering to specifications—we strive to deeply understand each customer’s intended application and design intent, and flexibly build machining methods and quality control systems tailored to those needs.

With responsibility and pride in every product we manufacture, we maintain an uncompromising commitment to quality, ensuring our customers receive products they can trust.

Our 75+ years of dedication and proven results stand as a testament to our technological expertise, and we will continue to challenge ourselves and evolve in pursuit of our corporate mission:

"Unwavering commitment to quality and delivering products that satisfy our customers."

JIS Q 9100

certification

Acquired

Hole making

NADCAP certification

Acquired

GE certification Acquired

Internal audit

The Key Point of Our Advanced Technology

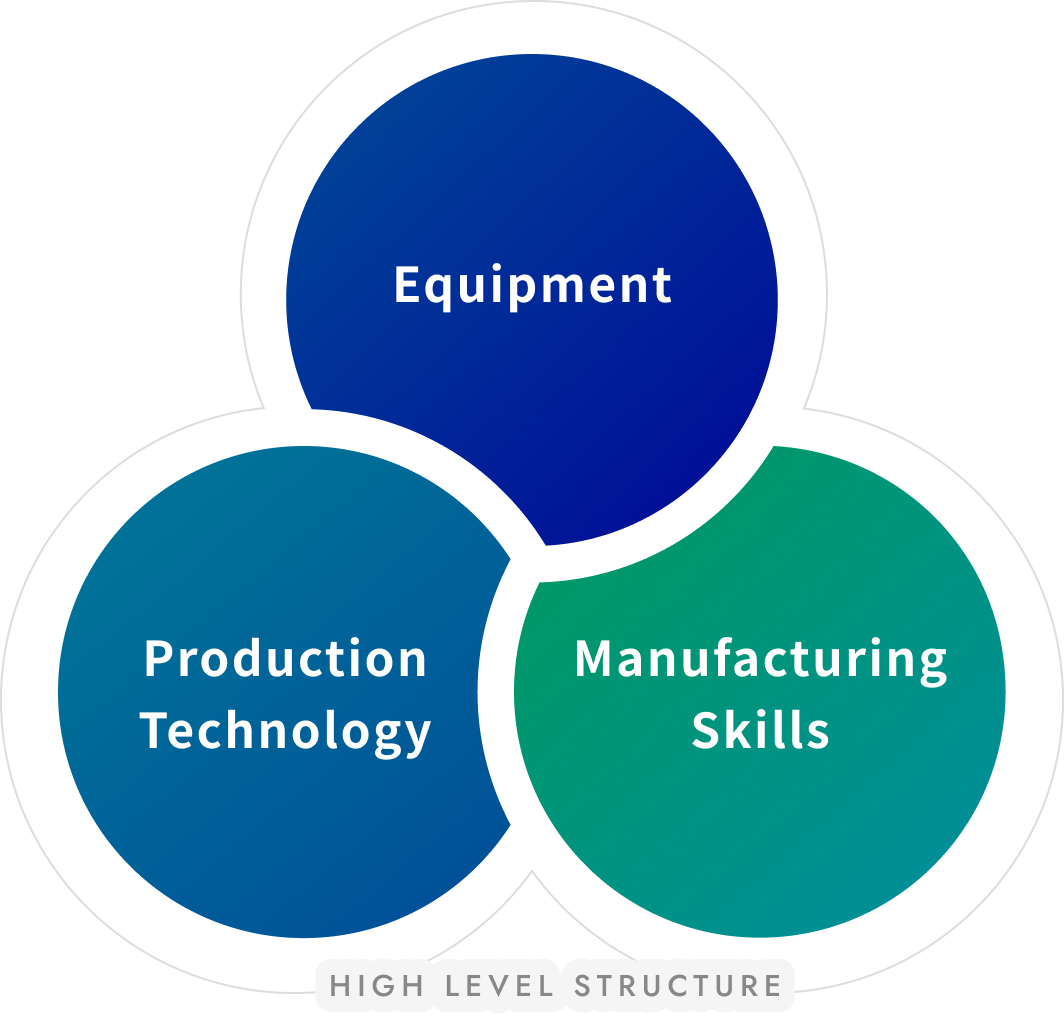

Our strength does not lie in a single standout factor such as "latest facility" or "highly skilled staff."

Rather, it comes from the well-balanced integration of multiple high-level elements: the superior quality of our facility, the reliability of our production engineering, and the advanced skills of our on-site personnel.

We not only introduce latest facilities, but also develop advanced production engineering to maximize its potential, and operate them with experienced, highly specialized staff.

What sets us apart is not simply having these three elements, but how closely they are integrated and how effectively they complement one another.

This synergy among “facility,” “technology,” and “staff” produces a level of technical capability that cannot be achieved by any one factor alone.

It is this comprehensive strength—our unique three-pronged approach—that enables us to respond flexibly and precisely to a wide range of customer needs, and stands as a competitive advantage that others cannot easily replicate.

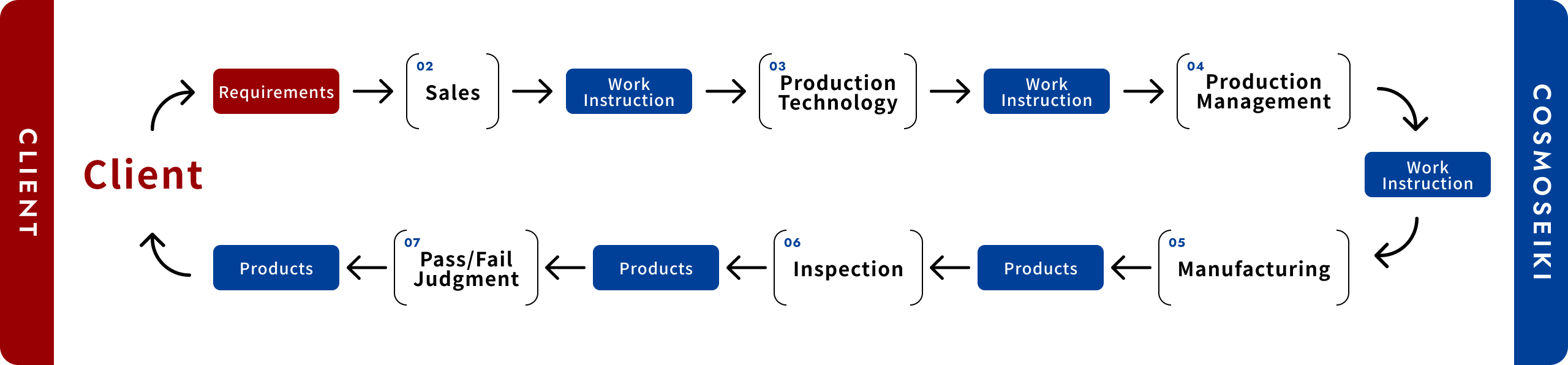

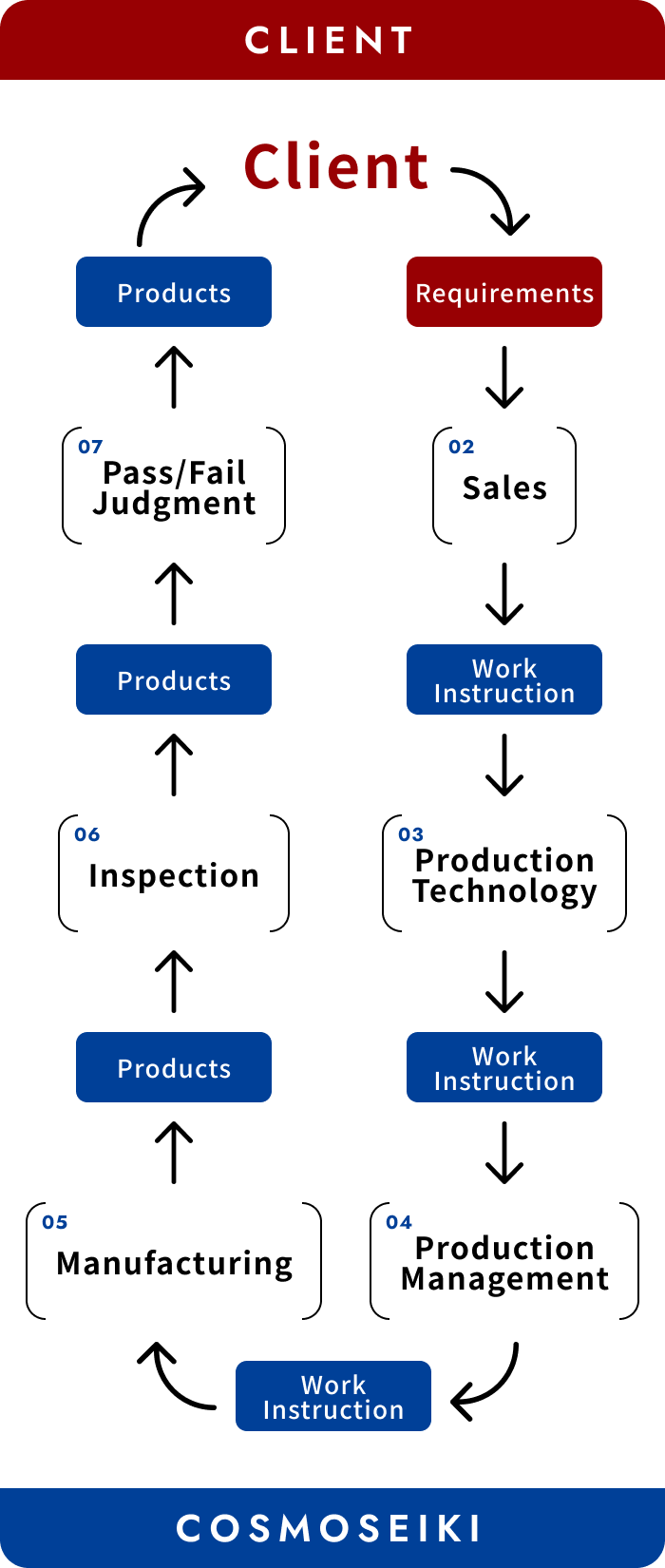

We Offer Fully Integrated Support from Material Procurement to Delivery

Our process begins with the sales team receiving an order from the customer. Taking into account the drawing specifications and quality requirements, our production engineering team then designs the manufacturing process, prepares work instructions, and readies the necessary jigs and tools—completing the production setup.

Once the required materials are procured, our manufacturing department carries out the machining work in accordance with the work instructions. The finished parts are thoroughly inspected to ensure they meet specified dimensions and high-quality products are delivered to our customers.